HELICORD AUTOMOTIVE RAW EDGE COGGED BELTS

THE MULTIPLE ADVANTAGE BELTS

1. Over 300% longer service life when compared with conventional belts.

2. Fewer retensions.

3. Higher efficiency.

HIGHER DRIVE EFFICIENCY

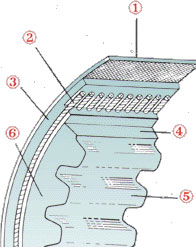

The multiple advantages are the result of state of the art process techniques and use of superior materials:

- Polychloroprene/EPDM impregnated fabric backing.

- Specially treated and stabilised Polyester cord.

- Polychloroprene/EPDM cushion.

- Polychloroprene/EPDM base with aligned reinforcing fibers.

- Integrally molded cogs.

- Raw Edge.

OVER 300% LONGER SERVICE LIFE. The use of superior polymer compounds with special antidegradants and specially treated reinforcing cords in HELICORD Raw Edge belts result in greatly increased life of the belt when compared with conventional belts.

FEWER RETENSIONS. The reinforcing Polyester cord is specially treated and stabilised which increases the modulus and greatly reduces stretch in service. This means fewer retensions and lower maintenance.

GREATER SAFETY. The use of specially treated reinforcing fibers with specially chemicals in the base ensures that HELICORD Raw Edge belts give optimum performance even in the hostile conditions under the bonnet.

HIGHER EFFICIENCY. The molded cog design of HELICORD Raw Edge belts ensures that hysteresis losses are reduced which translates to higher overall efficiency of the drive